- 0 Comments

- By admin

- Our Blog Services Related

- 326 Likes

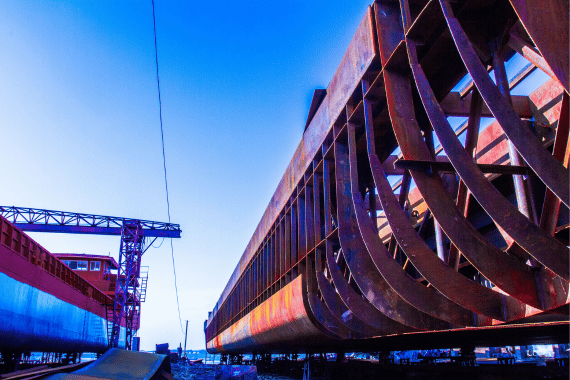

Building a barge is a complex process that requires extensive knowledge and experience in naval architecture, engineering, fabrication, and project management. In this article, we will take a closer look at the step-by-step procedure for constructing a barge, including the necessary materials, tools, and techniques.

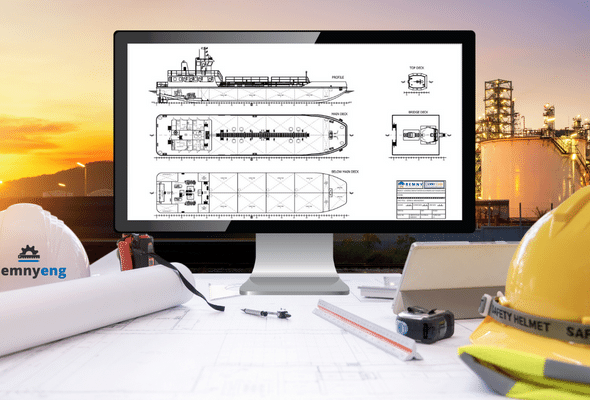

Planning and Design

The first step in building a barge is to design the barge. A naval architect and ship designer create a detailed plan and design. This includes determining the size and shape of the barge, as well as the required materials and equipment. The following are key considerations during the planning and design stage:- Purpose of the barge: Will it be used for transportation, storage, or construction purposes?

- Payload capacity: What is the maximum weight the barge can carry?

- Dimensions: What are the length, width, and height of the barge?

- Materials: What materials will be used to build the barge?

- Safety requirements: What safety features are necessary to meet industry standards and regulations?

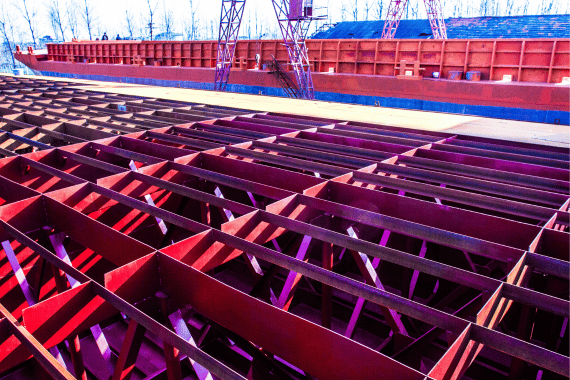

Fabrication

Once the planning and design stage is complete, the next step is to begin fabrication. This involves cutting, welding, and assembling the components of the barge. The following are the key steps in the fabrication process:- Cutting: The metal sheets are cut according to the design specifications using a plasma cutter, laser cutter, or other cutting tools.

- Welding: The cut sheets are then welded together to form the hull of the barge. This process requires skilled welders and specialized welding equipment.

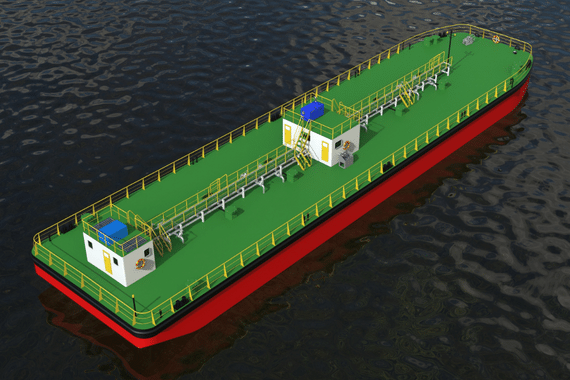

- Assembly: Once the hull is complete, other components such as the deck, superstructure, and machinery are installed and assembled.

Painting and Coating

Once the barge is fully assembled, it must be painted and coated to protect it from corrosion and weathering. The following are the key steps in the painting and coating process:- Surface preparation: The surface of the barge is cleaned, degreased, and blasted to remove any contaminants and rust.

- Primer: A primer is applied to the surface to create a smooth and even base for the topcoat.

- Topcoat: A topcoat is applied to the surface to provide a durable and protective layer. This can be a single or multi-layer coating, depending on the requirements.

- Maintenance: Regular maintenance is required to keep the barge in good condition, including periodic inspection, cleaning, and touch-up painting.

Launching, Testing and Delivery

The final step in the barge building process is launching and testing. This involves moving the barge to the water and conducting various tests to ensure that it meets the required standards and specifications. The following are the key steps in the launching and testing process:- Transportation: The barge is transported to the water using a specialized trailer or crane.

- Launching: The barge is launched into the water using a slipway, a marine railway, or a crane.

- Inspection: The barge is inspected to ensure that all components are properly installed and functioning correctly and that the barge meets the required standards and specifications.

- Load testing: The barge is loaded with weights or cargo to test its payload capacity and stability.

- Water trials: The barge is taken out to sea or a body of water for a series of sea trials. This involves testing its performance under various weather conditions, including speed, maneuverability, and stability.

- Final adjustments: Any necessary adjustments or modifications are made to ensure that the barge meets the required standards and specifications.

- Delivery: Once the barge has passed all tests and inspections, it is ready for delivery to the client.

Leave Your Comment